Read this quick article on Carlsberg to learn how they did it, and remember, we can scale it down for smaller manufacturers too. Thingworx is now more modular than ever, allowing a manufacturer to scale over time instead of investing a ton upfront for a fully customized solution. Thingworx, a PTC technology, is a connected manufacturing solution based on IoT (Internet of Things connectivity) that can help even smaller manufacturers start to achieve more sustainability in their production processes, and achieve cost savings in operations. No, you don't have to spend a fortune to start implementing a data and analytics system Find one that can scale with you over time.

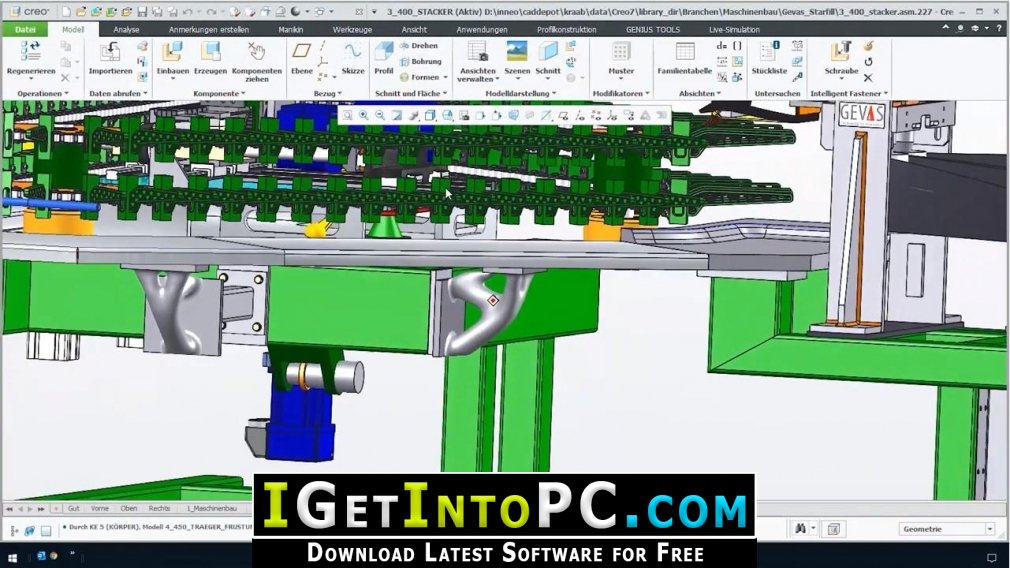

File formats edit This section needs expansion. It connects to PTC’s other solutions that aid product development, including Windchill for Product Lifecycle Management (PLM), Mathcad for engineering calculations and Arbortext for enterprise publishing software. Smaller manufacturers can start taking steps to reduce their scrap and waste and improve OEE just by implementing a platform to collect and analyze production data. Creo is part of a broader product development system developed by PTC. Sustainability doesn't just need to be limited to the big guys, however. I've been reading a lot about sustainability initiatives becoming a primary driver for new technology adioption at larger manufacturers.

0 kommentar(er)

0 kommentar(er)